PNCR

PNCR SCR

SCR SNCR

SNCR Semi-dry system

Semi-dry system Dry system

Dry system Photovoltaic

Photovoltaic Case

Case

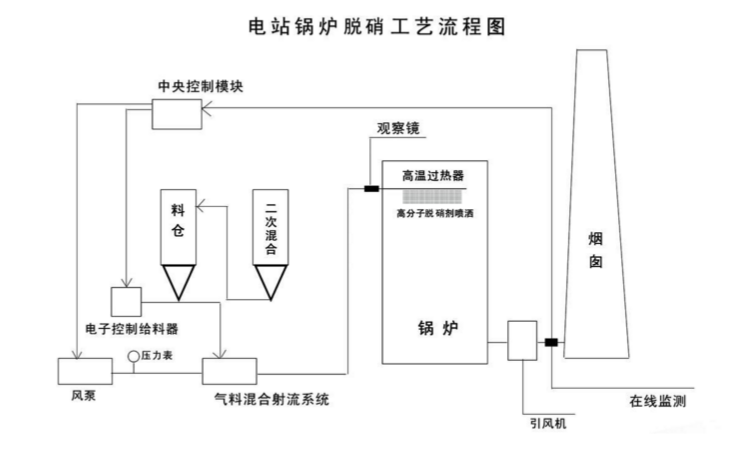

PNCR denitrification process system

The polymer denitrification process (PNCR denitrification process) is an engineering design using computational fluid dynamics (CFD) and chemical kinetics model (CKM), namely advanced virtual reality design technology with the size, fuel type and characteristics of a specific combustion device, decomposition furnace The engineering design is carried out by combining the load range, combustion method, excess air in the furnace, initial or baseline NOx concentration, furnace flue gas temperature distribution, furnace flue gas flow rate distribution, and so on. Used in cement plants, power plants, and most kiln furnaces to meet NOX emissions requirements. The concept of denitrification using polymer powders is to select a suitable feed position, so that the denitration agent and the flue gas are fully mixed and sprayed into the flue gas to react with NOx to achieve the purpose of denitrification. The products are H2O, N2, CO2, and others. Non-toxic gases and the usual flue gas composition.

Process Introduction:

Automatic adjustment based on NOX concentration →

↓

Denitrification agent → Silo → Adjustable feeder → Enter the furnace800℃-900℃High temperature area → Clean flue gas

↑

Roots blower →

|

PNCR storage and delivery system

|

PNCR distribution system  PNCR injection system |

Prev:None